Poddar Pigments

About Poddar Pigments

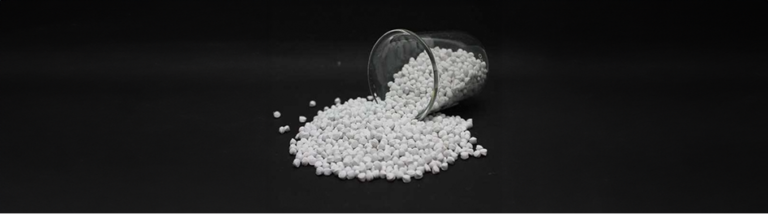

Poddar Pigments is a leader in colour and additive masterbatches, serving the plastic and synthetic fibre industries. Its product range includes colour, additive, and filler masterbatches designed for high-performance applications in textiles, packaging, and automotive. With a focus on quality and innovation, Poddar delivers consistent results and customized solutions for every formulation need. The brand continues to support sustainable and efficient manufacturing through advanced pigment technology.

Key Products

-

Color Master batches

-

Fire Retardant

-

Antimicrobial Masterbatch

-

UV Stabilized Masterbatch

-

White Masterbatches

-

Antiblock

-

Antistatic Masterbatch

-

Slipping Agent

-

Antioxidant

-

Optical Brightener

-

Diffuser Masterbatches

-

Antifog Masterbatches

-

Polymer Processing Aid (PPA)

Poddar Pigments is your ultimate destination for top-notch masterbatch solutions. Discover the unparalleled difference in quality and economics that our masterbatches can bring to your film production processes.

Our specialized masterbatches are characterized by their high pigment loading in a compatible carrier resin, ensuring superior dispersion, exceptional heat stability, and long-lasting color vibrancy. Engineered for efficiency, they require minimal dosing levels, enhancing the overall quality of your films while providing a cost-effective solution for your production needs. Choose Poddar Pigments for Monolayer & Multilayer films and unlock a new level of excellence in your production.

Key Features

Excellent Heat Stability :

Maintain the structural integrity of your product and ensure it can withstand varying temperature conditions.

Excellent Dispersion:

Achieve uniform and vibrant colors, and enhance the visual appeal of your product.

Color Consistency:

Ensure that your product maintains a consistent and attractive appearance, meeting your quality expectations.

Applications

Our PPFR (Polypropylene Flame Retardant) masterbatch is a versatile solution for various end uses :

Carpets

Enhance fire resistance in residential and industrial carpets and ensure your safety.

Automotive Fabrics

Protect automotive components and interiors from fire-related hazards.

Textiles

Elevate safety in woven and knitted fabrics used in upholstery, baggage, furnishing, wall and floor coverings, and draperies.

Non-wovens

Ensure fire safety in non-woven products that are used for industrial and geological services.

Technical Standards

PPL's flame retardant masterbatch complies with several industry standards and ensures enhanced safety and reliability:

DIN-4102-B2

FMVSS-302

16 CFR-1631 (FF-2-70)

Our PPFR (Polypropylene Flame Retardant) masterbatch is a versatile solution for various end uses.

Key Features

PPL's flame retardant masterbatch complies with several industry standards and ensures enhanced safety and reliability:

DIN-4102-B2

FMVSS-302

16 CFR-1631 (FF-2-70)

Applications

Our PPFR (Polypropylene Flame Retardant) masterbatch is a versatile solution for various end uses :

Carpets

Enhance fire resistance in residential and industrial carpets and ensure your safety.

Automotive Fabrics

Protect automotive components and interiors from fire-related hazards.

Textiles

Elevate safety in woven and knitted fabrics used in upholstery, baggage, furnishing, wall and floor coverings, and draperies.

Non-wovens

Ensure fire safety in non-woven products that are used for industrial and geological services.

Our Antimicrobial Masterbatch is specially formulated to provide long-lasting protection against harmful microbes such as bacteria, fungi, and viruses. Ideal for applications in healthcare, packaging, consumer goods, and more, this masterbatch helps maintain hygiene, reduce odor, and extend product life. It is compatible with a wide range of polymers and easy to integrate into your manufacturing process.

Salient Features

- Ultra fine dispersion ensuring good spinning performance.

- High Thermal Stability

- Multiple functional characteristics against all types of bacteria and pathogens.

Applications

- Carpets (Floor coverings)

- Knitted Fabrics (Socks, Sportswear and undergarments etc.)

- Woven Fabrics (Medicinal and Sanitary clothing)

- Household Textiles (Upholsteries, Textile Wall coverings, Garments etc)

- Non woven - Hospitals and other sanitary supplies.

Our UV Stabilized Masterbatch is specially formulated to protect polymers from the damaging effects of ultraviolet (UV) radiation. It helps prevent cracking, fading, and brittleness caused by prolonged outdoor exposure. Designed for use in outdoor applications like agriculture films, automotive parts, packaging, and construction materials, this additive ensures long-term durability and product integrity.

Key Features

Comprehensive UV Protection

PPL’s PP additive UV stabilizers provide robust protection, ensuring that the PP items remain unaffected by UV-induced damage.

Extended Product Lifespan

Our UV stabilizer additives enhance the longevity of the PP materials, safeguarding their structural integrity and appearance even over time.

Applications

Poddar Pigments Limited's PP additive UV stabilizers find application in various industries that include :

Outdoor Furnishing

Protect outdoor furniture from fading and degradation caused by UV exposure.

Automotive Components

Enhance the longevity of automotive parts that are exposed to sunlight.

Packaging

Preserve the integrity and appearance of the PP packaging materials.

Construction

Preserve the integrity and appearance of the PP packaging materials.Ensure the durability and aesthetics of the PP construction materials used in outdoor settings.

White Masterbatch is a concentrated blend of titanium dioxide (TiO₂) and polymer carriers, designed to impart brilliant whiteness, excellent dispersion, and high opacity. It ensures consistent color, thermal stability, and smooth processing across various manufacturing conditions.

Key Features

Enhanced Aesthetics

PPL's PP White Masterbatches and Optical Bright Masterbatches provide a visually appealing finish to PP products, making them stand out in the market.

Applications

Our PP White Masterbatches and Optical Bright Masterbatches find versatile applications across various industries :

Packaging

Elevate the visual appeal of PP packaging materials and make them more attractive to consumers.

Textiles

Achieve vibrant colors and a premium finish for PP-based textile products.

Automotive

Enhance the aesthetics of automotive components and interiors and create a visually appealing driving experience.

Consumer Goods

Add a touch of sophistication to PP consumer goods and make them more desirable in the market.

Anti-blocking agents prevent the blocking between two smooth films that are placed in contact with each other. The anti-blocking agents work by reducing the contact between the two layers, which reduces the coefficient of friction between the layers thereby preventing the blocking. The anti-blocking properties of the additive depend on – the particle size, distribution of particle size, particle shape, and the nature (organic vs inorganic) of the additive.

Key Features

Excellent Dispersion

Our masterbatches ensure even dispersion in the base polymer, thereby guaranteeing consistent results.

Low Haze Value

Say hello to films with exceptional clarity, thanks to our masterbatches that give clear output.

Reduced Blocking

By minimizing the contact and friction between film layers, our masterbatches effectively reduce blocking issues.

Polymers, especially those used in the manufacturing of films and fibers, are prone to building up static charges due to their large surface area-to-volume ratio. This static charge buildup can result in various undesirable consequences in the final product. Often, this also leads to many issues during processing, like difficulties in the winding films or melt-spun fibers, the clumping of powders during transport, and the adhesion of films during manufacturing.

At Poddar Pigments Limited, we offer a solution to combat these challenges with our specialized antistatic masterbatches. Specifically designed for PE and PP applications, our masterbatches effectively control surface resistivity and ensure that the static charges are kept in check.

Key Features

Excellent Dispersion

Our masterbatches disperse seamlessly, ensuring uniform antistatic performance.

Food Contact Approvals

Our products meet the highest and most stringent safety standards for food contact applications.

Slip masterbatches are invaluable additives in the world of packaging and film manufacturing. They serve a crucial role in reducing the coefficient of friction (COF) between film layers which helps to enhance the surface finishing of various products. In addition to minimizing friction, they also provide lubrication, creating a smooth layer on packaging films, which makes them easier to handle and package.

Poddar Pigments Limited offers a diverse range of slip masterbatches with PE and PP carriers that are designed to deliver exceptional slip performance. Even at very low dosages, our masterbatches effectively reduce COF, thereby contributing to the ease of processing and packaging.

Key Features

Low COF

Our masterbatches are formulated to significantly lower the coefficient of friction, which ensures smoother film handling.

Plastics are versatile materials used in various applications. However, they are susceptible to thermo-oxidative degradation during processing and usage. This degradation can occur due to several factors, including exposure to higher temperatures, high shear rates, and the effects of light and oxygen.

Poddar Pigments Limited offers a comprehensive range of antioxidant masterbatches and heat stabilizers that are designed for PE- and PP-based applications. These masterbatches are formulated to protect your plastics from the harmful effects of thermo-oxidative degradation, ensuring their longevity and performance.

Key Features

Effective Protection

Our masterbatches shield plastics from thermo-oxidative degradation, preserving their strength and appearance.

Application Versatility

Our masterbatches are suitable for a wide range of PE and PP applications.

Optical brighteners play a pivotal role in maintaining the brilliance and vibrancy of colors over time. These innovative additives are designed to counteract the natural yellowing that materials usually undergo due to various factors. At Poddar Pigments Limited, we offer a wide range of optical brighteners that are tailored to different polymer matrices, each with a specific active content.

Discover our diverse selection of optical brighteners, each meticulously crafted to preserve and enhance the color brilliance in your materials. Our products are engineered to effectively combat yellowing, thereby ensuring that your colors remain as vivid as they were on the day they were created.

Key Features

Reduction of Yellowing

Our optical brighteners effectively reduce yellowing and extend the life of your materials.

Polymer Compatibility

We provide brighteners for various polymer matrices and accommodate a wide range of applications.

Craft a Meta Description

Enhance color vibrancy and combat yellowing with our versatile range of optical brighteners that are tailored to different polymer matrices. Explore our products today.

At Poddar Pigments Limited, we proudly introduce our exceptional Diffuser Masterbatch. This cutting-edge product is meticulously designed to revolutionize the dispersion of light. Therefore, it ensures a perfect balance of haze, transmission, and diffusion. We specialize in enhancing the optical properties of polycarbonate sheets and LED lights and creating an environment of brilliance.

Key Features

Effective Light Dispersion

Our masterbatch effortlessly spreads light and ensures even illumination. This enhances the visual appeal of your products.

Perfect Haze Control

Achieve the ideal level of haze and strike the perfect balance between transparency and diffusion.

Tailored for Polycarbonate Sheets and LED Lights

We understand the unique demands of polycarbonate sheets and LED lighting, and our masterbatch has been expertly formulated to meet those specific requirements.

Experience the future of plastic film clarity with Poddar Pigments Limited's exceptional Antifog Masterbatch. This groundbreaking additive is engineered to prevent the formation of fog inside plastic films, with the primary focus on applications in food packaging and agricultural films.

Key Features

Sustained Transparency

Our masterbatch preserves the clarity of plastic films and ensures that your products are showcased in their best light.

Extended Freshness

Keep food fresher for longer with the antifog properties of our masterbatch and add value to your food packaging.

Enhanced Light Transmission

Achieve better light transformation, which will present your products with a natural and appealing radiance.

Thermal Stability

The masterbatch's thermal stability ensures consistent performance even under varying temperature conditions.

Discover the superior capabilities of PPA (Polymer Processing Aid) Masterbatch at Poddar Pigments Limited. Available in both PE and PP carriers, our PPA Masterbatch is tailored for a wide range of applications, including films, PP sheets, raffia/tape, lamination, PP spun-bonded non-woven fabric, and various injection-molded products like caps, home appliances, and household items.

Key Features

Enhanced Polymer Flow

Our PPA Masterbatch optimizes polymer flow, ensuring smoother and more efficient processing.

Increased Productivity

You can boost your productivity with streamlined manufacturing processes, which would consequently allow you to efficiently meet demand.

Reduced Die Buildup

Our masterbatch eliminates frustrating die buildup issues, helping you minimize downtime and maintenance.

Decreased Filter Press Usage

Our PPA Masterbatch helps to reduce filter press requirements, saving both time and resources.