Celanese CMI

Celanese Corporation - a global leader in specialty materials

Celanese CMI, the Indian division of Celanese Corporation, specializes in engineering polymers with a focus on innovation and quality. Its range includes PA6 & PA66, PP, ABS, PC, and PMMA, widely used across automotive, consumer, and industrial applications. Designed to meet modern manufacturing demands, these materials provide excellent mechanical strength, thermal stability, and processing ease. Celanese CMI’s strong technical support and customer-driven solutions make it a trusted partner across industries.

Key Products

-

PA 6 & PA 66 (Polyamide / Nylon)

-

Polypropylene Compounded(PP)

-

ABS (Acrylonitrile Butadiene Styrene)

-

Polycarbonate (PC)

-

PMMA (Polymethyl Methacrylate)

PA 6 & PA 66 (Polyamide / Nylon)

Celanese PA 6 and PA 66 are high-performance engineering thermoplastics known for their strength, toughness, and excellent mechanical properties.

These materials are widely used in industries requiring high durability and resistance to wear, moisture, and chemicals.

Key Features

- High mechanical strength and impact resistance

- Good chemical and abrasion resistance

- Thermal stability and dimensional reliability

- Excellent fatigue resistance for long-life performance

Applications

- Automotive parts (under-the-hood components, brackets, and housings)

- Industrial machinery (gears, bearings, conveyor parts)

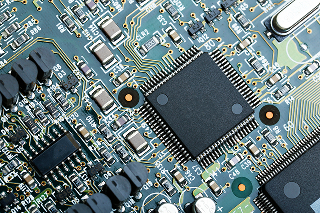

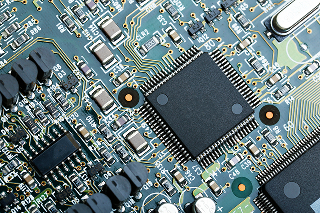

- Electrical and electronic components (connectors, switch housings)

- Consumer goods (power tool housings, sporting goods)

Polypropylene Compounded (PP)

Celanese Polypropylene Compounded (PP) is a lightweight, versatile thermoplastic offering an excellent balance of cost, mechanical strength, and chemical resistance. Beyond standard grades, Celanese provides compounded PP solutions with tailored additives such as glass fibers, talc, minerals, and impact modifiers to meet demanding performance requirements across industries.

Key Features

- Low density, enabling lightweight designs

- Excellent resistance to chemicals and moisture

- Good fatigue strength and impact resistance

- Wide formulation flexibility with glass-filled, talc-filled, mineral-reinforced, flame-retardant, and UV-stabilized compounds

- High suitability for high-volume, cost-efficient production

Applications

- Automotive: Structural and interior parts, trims, panels, ducts, under-the-hood components (reinforced with glass or talc-filled PP)

- Consumer Goods: Containers, caps, living hinges, durable housings

- Industrial: Heavy-duty packaging, storage solutions, appliance components

- Healthcare: Disposables, housings for diagnostic and medical devices

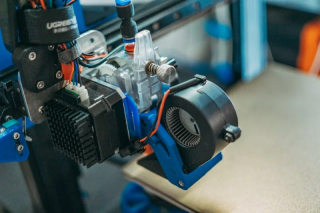

ABS (Acrylonitrile Butadiene Styrene)

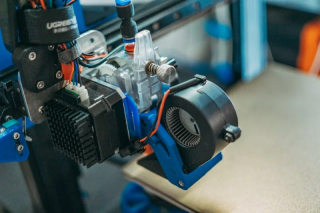

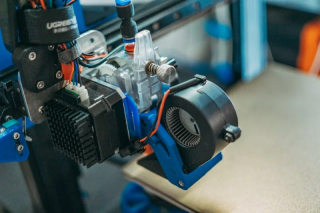

Celanese ABS is a durable, impact-resistant thermoplastic with excellent aesthetic qualities, making it ideal for both functional and decorative parts. It is known for its ease of processing and ability to produce complex parts with high-quality surface finishes.

Key Features

- Outstanding impact strength, even at low temperatures

- Smooth, high-gloss surface finish

- Good dimensional stability and rigidity

- Chemical and stress-crack resistance

Applications

- Automotive interiors (dashboards, trim components)

- Consumer electronics (device housings, printer casings)

- Household appliances (vacuum cleaners, blenders)

- Toys and recreational products

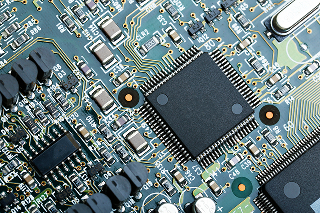

4. Polycarbonate (PC)

Celanese Polycarbonate (PC) is a transparent, high-performance thermoplastic that combines excellent optical clarity with high impact strength, making it ideal for applications requiring both visibility and durability.

Key Features

- High impact resistance and toughness

- Excellent optical clarity and light transmission

- Heat resistance up to 135°C

- Good dimensional stability and flame resistance

Applications

- Automotive lighting (headlamp covers, interior lenses)

- Safety equipment (helmets, face shields, goggles)

- Electrical housings and connectors

- LED lighting components and lenses

PMMA (Polymethyl Methacrylate)

Celanese PMMA, also known as acrylic, is a rigid, transparent thermoplastic that offers excellent optical properties, UV resistance, and weatherability. It is commonly used as a lightweight, shatter-resistant alternative to glass in both indoor and outdoor applications.

Key Features

- High light transmission and optical clarity

- Excellent UV and weather resistance

- Good surface hardness and scratch resistance

- Easy to fabricate and thermoform

Applications

- Signage and light guides

- Automotive lighting (tail lights, indicator lenses)

- Display panels and protective screens

- Architectural glazing and design elements